Finished Product

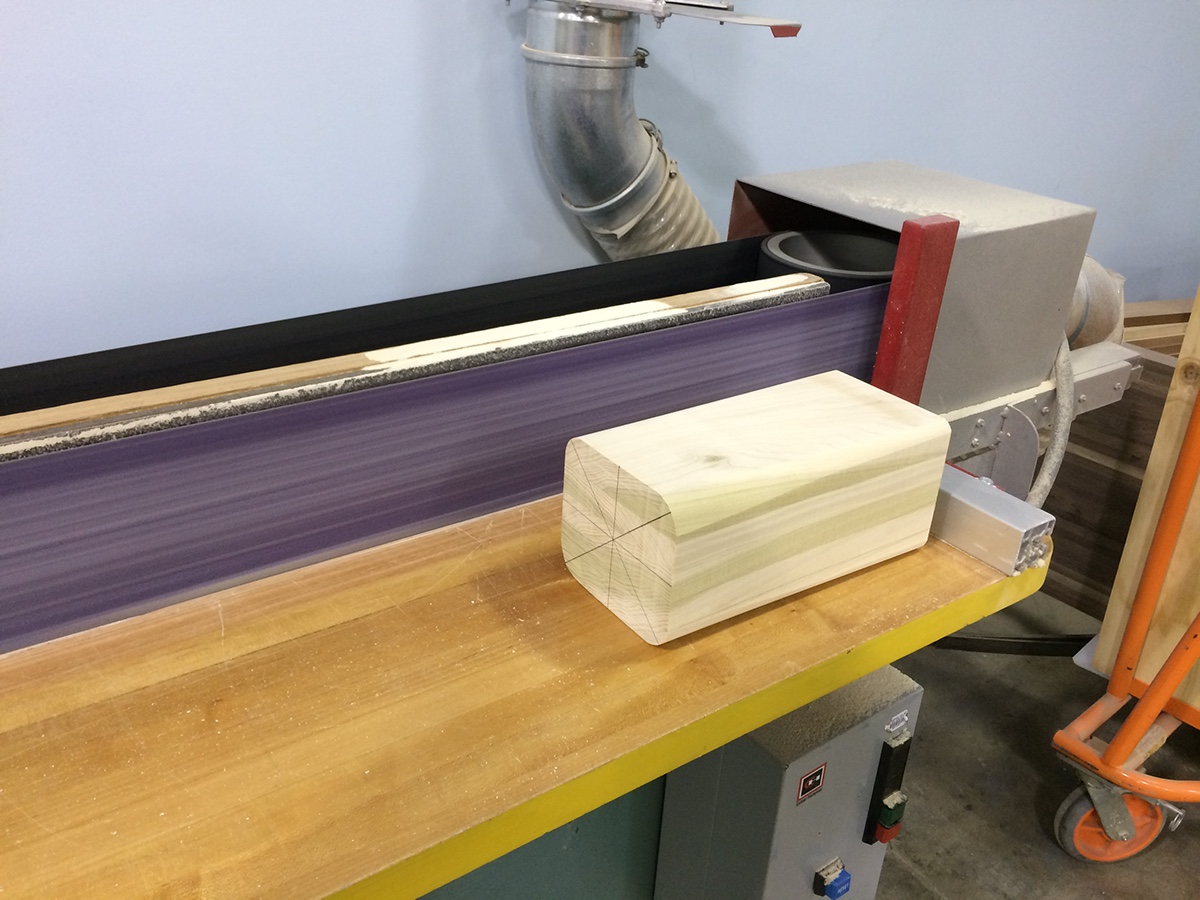

Aftter miling the lumber it was glued into a block and sanded to be turned on the wood lathe.

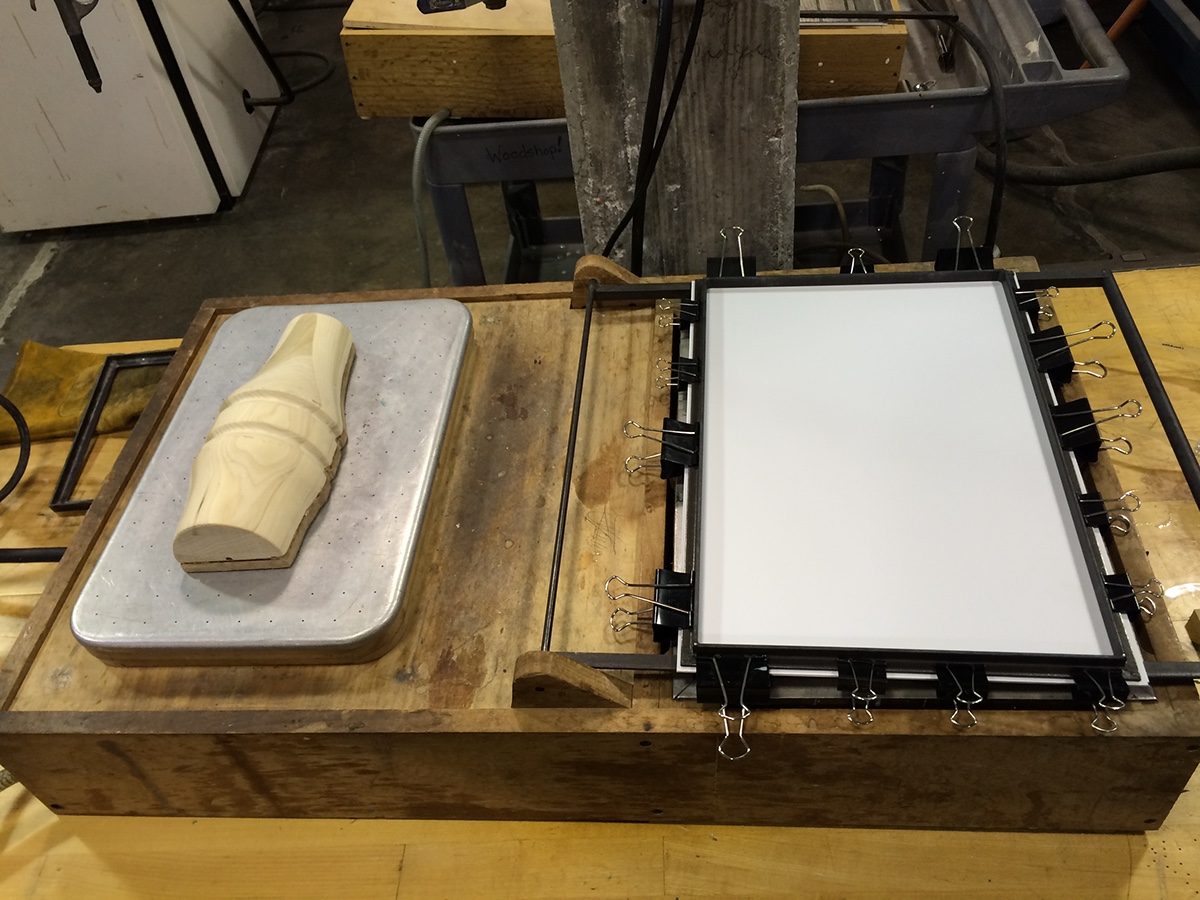

Once the design was turned into the block it was cut in half and a piece of MDF was attched to the bottom and cut. It was ready for vacuum forming.

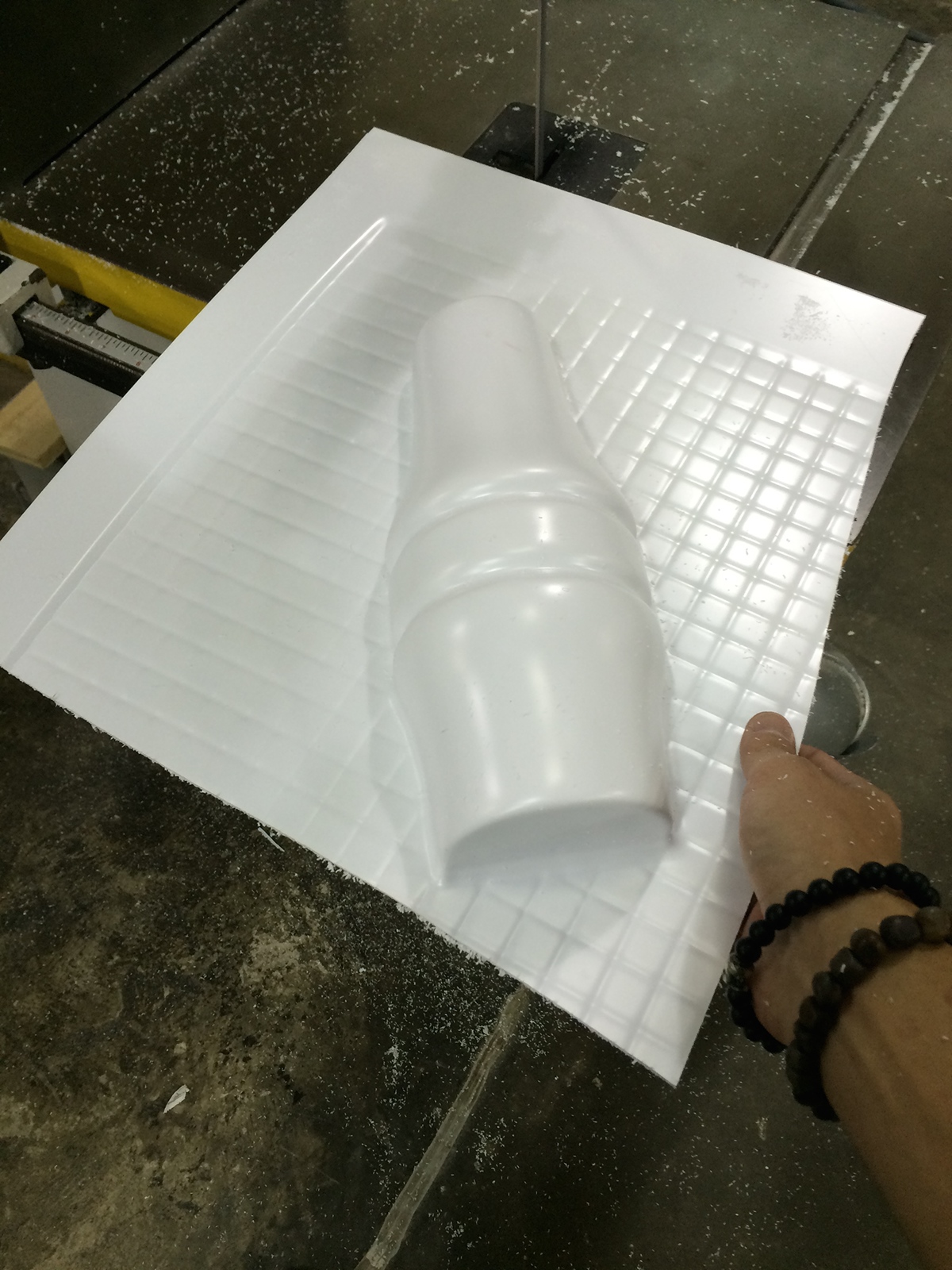

Once the vacuum forming was complete the silhouette was cut out and and put on a router.

Two Halfs where made and then sanded and attached together where all the seams and inperfections where smoothed out before painting.

Painting in process after sanding of the Bondo.