Photo credit: Amy Hunter Photography

Photo credit: Amy Hunter Photography

Photo credit: Amy Hunter Photography

Photo credit: Amy Hunter Photography

Photo credit: Amy Hunter Photography

Photo credit: Amy Hunter Photography

Photo credit: Amy Hunter Photography

The beginning of patterning. The last is taped, then the tape is peeled off and stuck down to pattern paper to get the form of the shoe. Lasts come in alll different sizes and styles.

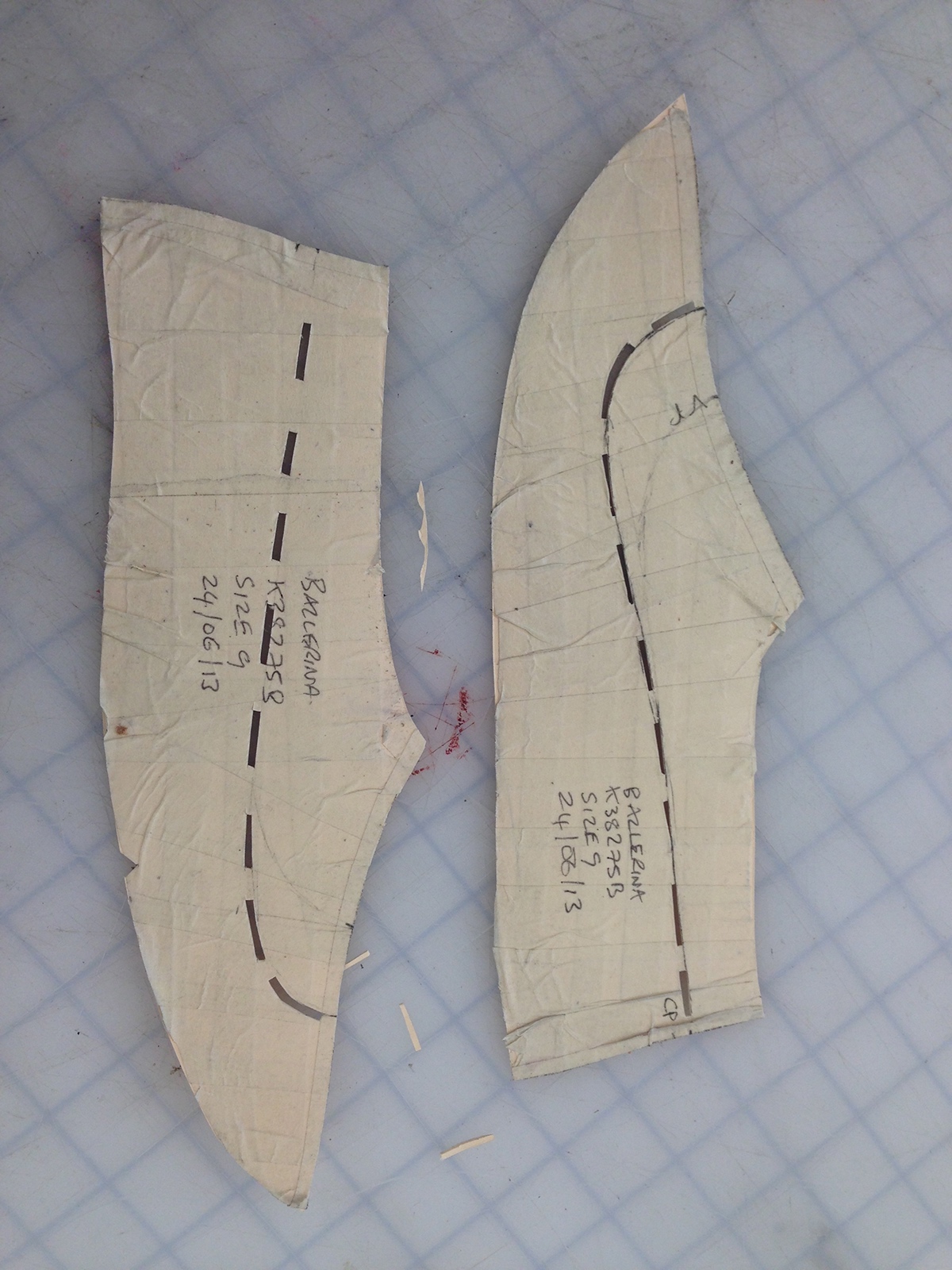

Pattern pieces

All of th pattern pieces for one pair of ballerinas.

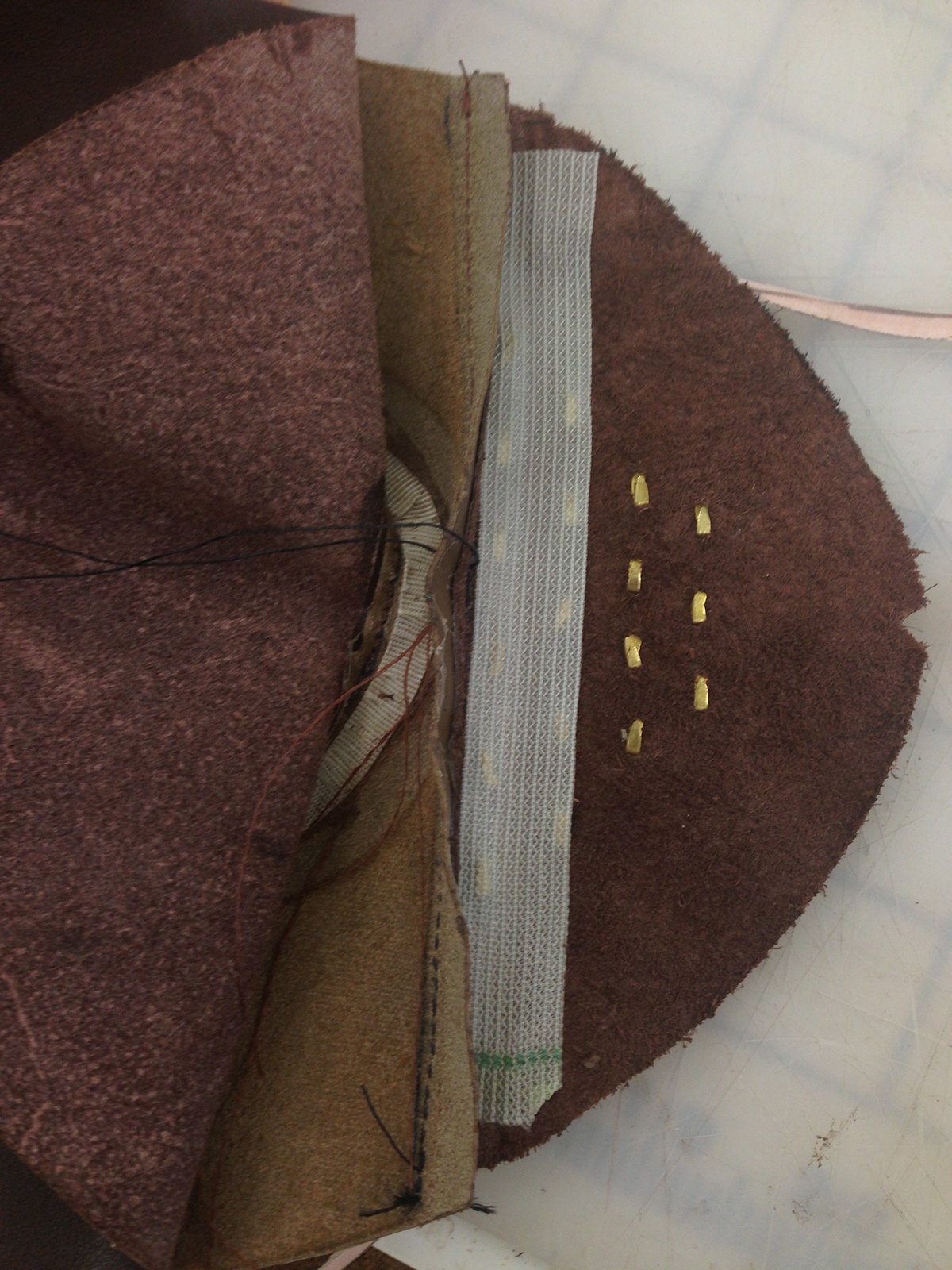

I use binder clips to hold the leather togeth while sewing. The two pieces of leather are sewn together face to face so that when it is opened the stitching is not visible.

The process of putting studs on the toe cap of the shoe.

Reinforcement tape is used to secure the studs. Top line tape is places along the edge of the top of the shoe between the lining and upper. The top cap is stitched to the upper of the shoe in the same way that the lining is so that the stitiching is invisible.

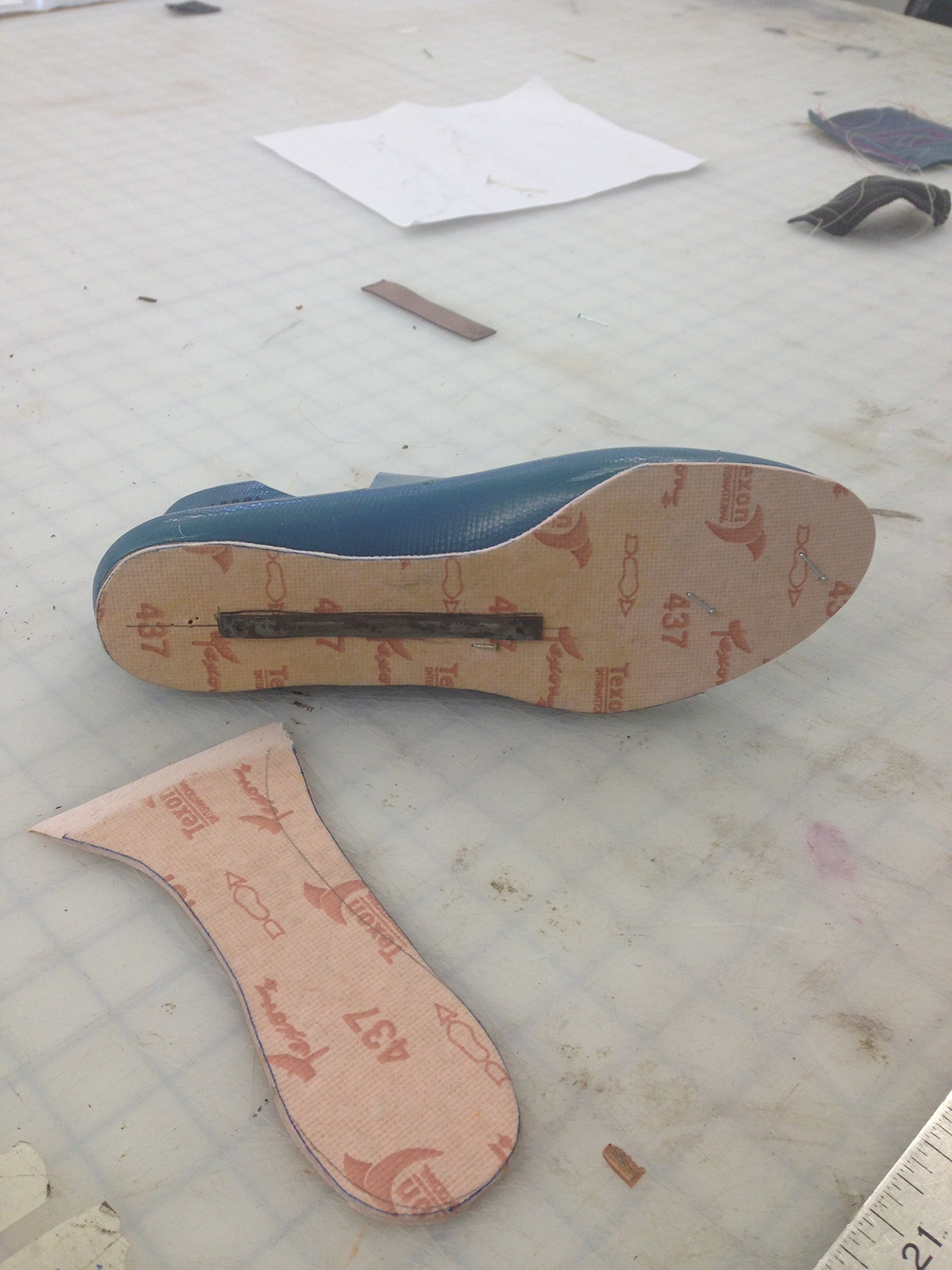

This shows the process of creating an insole and adding a shank to the shoe. Industrial shoes have shanks in them, as well. The shank serves as a supportive structure in the shoe.

This shows the shoes toe caps. Many shoes have toe caps and heel stiffners to give the shoe more support.

I refer to this as "breaking the last." This is what the last must do to remove the shoe.

The sock is the last thing added to the shoe before it is ready to be worn.

Final Product.